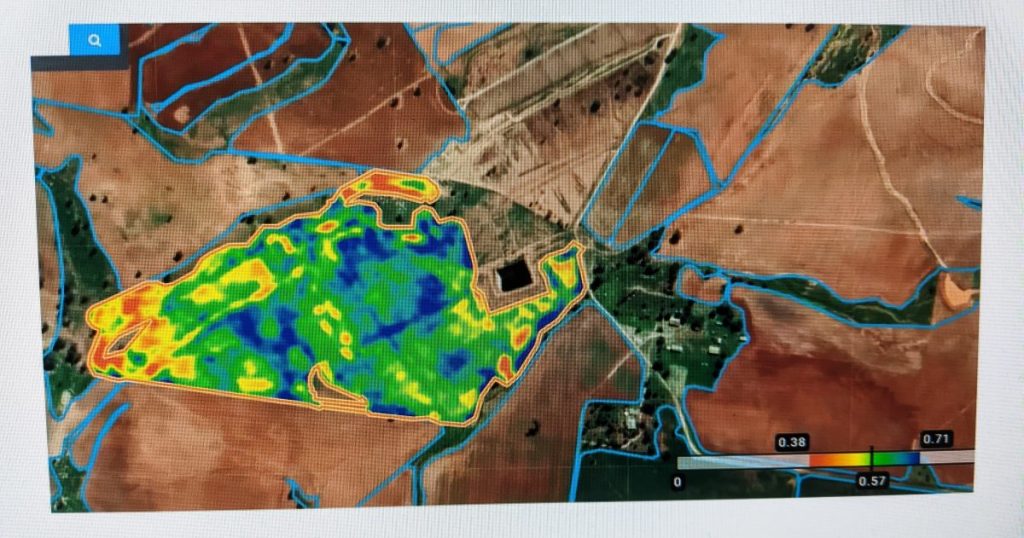

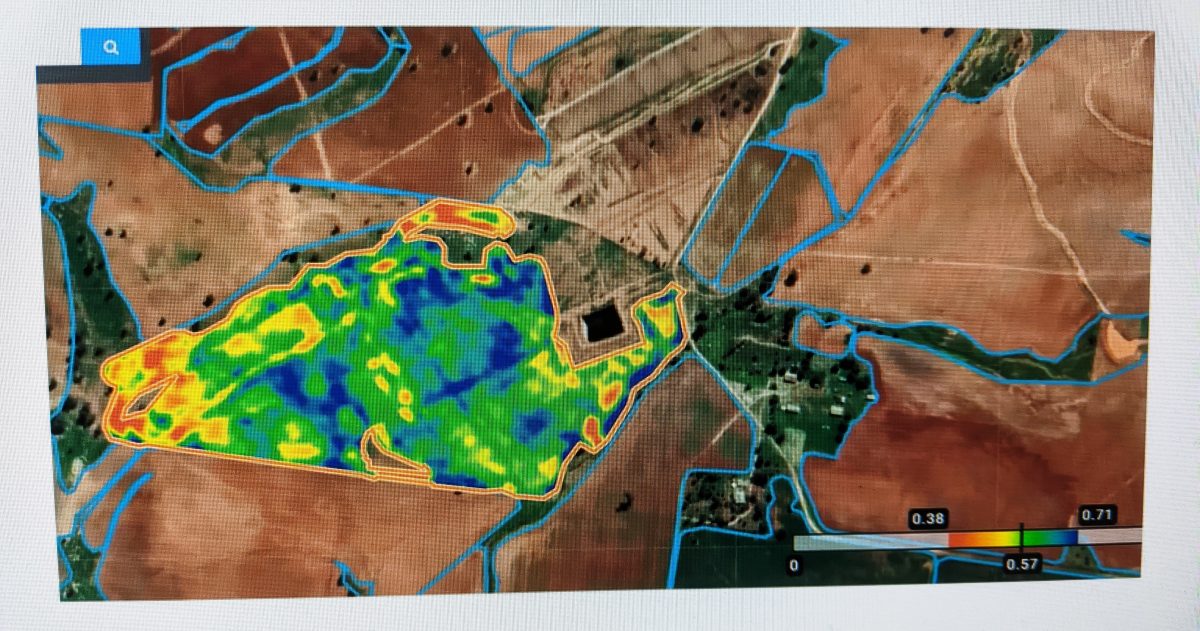

An NDVI picture from DataFarming of a paddock at Gollan east of Dubbo, the place uneven germination and waterlogging are warranting using VR nitrogen software. Picture: Binginbar Farms

VARIABLE-RATE (VR) nitrogen software is delivering optimistic outcomes for 3 New South Wales growers who’re transferring into precision agriculture for various causes, and shared their experiences in a webinar on Wednesday hosted by DataFarming.

The Toowoomba-based software program firm makes use of NDVI imaging from satellites as a method for growers to entry low-cost recordsdata growers can use to information their tools in VR purposes, and the webinar heard from two growers who’re utilizing them, and one who is just not.

The webinar was watched by round 300 registered viewers, together with growers, agronomists and researchers, and DataFarming managing director Tim Neale stated the session was designed to indicate how precision agriculture can assist overcome seasonal and long-term hurdles.

The largest this season has been excessive fertiliser costs, and waterlogging has additionally been evident as an inhibitor of fertiliser effectivity.

Talking after the webinar, Mr Neale stated DataFarming was intently monitoring the uptake of VR.

Tim Neale

“We haven’t received the precise numbers but, as there’s nonetheless loads of crop being planted,” Mr Neale stated.

“Canola is usually in, however wheat and barley are means behind.

“We’re simply beginning to see the kick up, and the rationale we have been operating the webinars is that we anticipate to see a large improve in VR use this season.”

N wanted regardless of previous pulse

Entitled Maximise Your Fertiliser Worth, the webinar heard first from Mark Day of Woodlea Ag Enterprises, who’s utilizing DataFarming’s fast zoning pictures at $0.50 per hectare to offer the “form file” which Mr Neale stated may be labored into most trendy machines.

Mr Day farms in a household partnership close to Lockhart within the southern Riverina, and runs a four-year rotation of pulses, canola, wheat and barley.

The Days received into variable-rate software for phosphorus substitute greater than 10 years in the past, and most of their nation has additionally had lime or gypsum added over that point.

“We haven’t been within the area of variable-rate nitrogen, despite the fact that we have now the tools to do it,” Mr Day stated.

“Nitrogen’s the massive factor in the mean time, and one thing we’re all battling with on how one can handle, particularly the value.”

Mr Day stated nitrogen deviations in a 450ha paddock of canola have been evident within the NDVI pictures out there by means of DataFarming, and a satellite tv for pc picture taken Could 22 offered the “form” for his or her first VR nitrogen unfold.

“On the time, we had sufficient for a 100kg/ha unfold, and simply wished to make use of that higher on the block.”

Mr Day stated the Could 22 DataFarming picture confirmed poorer zones wanted extra nitrogen, and the crop was “fairly effectively flying” in higher zones.

Canola has a giant urge for food for nitrogen and, regardless of the paddock having faba beans final 12 months following wheat the 12 months earlier than, Mr Day gave good zones 80kg/ha, common ones 100kg/ha and poor ones 140kg/ha.

The train used 44.5t in complete over the paddock with variable soil varieties.

Latest moist climate means the upcoming in-crop urea software might be a flip of the earlier.

“Now we’ll do the reverse; these blocks which were waterlogged… are going to be restricted, and we’ll in all probability push the dry nation a bit more durable now.”

Shallow soils a problem

At Gollan, 50km east of Dubbo, the Simpson household crops round 3000ha of the 3850ha Binginbar Farms in a canola-barley-wheat rotation on what Nathan Simpson described as “very variable soils” ranging in depth from round 10cm to 1 metre.

“We’ve received a really shallow bucket.”

“We simply can’t retailer moisture like among the black-soil nation can.”

Binginbar additionally runs sheep, and has used DataFarming pictures to information variable-rate purposes this and final 12 months.

Mr Simpson stated DataFarming’s pictures have been getting used this 12 months to assist rectify the affect from a less-than-ideal seeding when a brand new air-seeder didn’t arrive in time for sowing, and contractors needed to be known as in to get planting accomplished.

“Notably this 12 months due to waterlogging and air-seeder points, it actually made sense to make use of single NDVI. “

Mr Simpson stated air-seeder blockages resulted in poor germination in patches, and these will get zero urea within the VR top-dressing.

“We haven’t saved any urea; that’s not the purpose of what we need to do.

“We need to maximise yield.”

Urea charges utilized primarily based on the DataFarming form have been zero, 50kg/ha and 100kg/ha for barley, and 0, 75kg/ha and 150kg/ha for canola and wheat.

“We’re about 20c/ha for these prescriptions, and it’s finished the job very well.”

“It’s too late…to repair up another stuff-ups, and all you are able to do is push yield potential the place it is sensible to.”

Solely a small variety of paddocks throughout Binginbar Farms aren’t getting VR nitrogen software, and Mr Simpson stated this was primarily as a result of they didn’t have a giant variation of soil varieties.

“Actually on 90 per cent of the nation there are massive variations.”

Mr Simpson stated not spending cash on poorly established sections of crop appears to be like to be a clever resolution, notably with waterlogging a difficulty in some paddocks.

“Areas with very low yield potential, we received’t be placing nitrogen on them.”

He stated nitrogen unfold on waterlogged nation would volatilise immediately.

“It could be a waste of cash.”

Binginbar has additionally used satellite tv for pc imagery and different information from Western Australian firm Laconik, and in 2020 did strip trials to check NDVI and their wider technique primarily based on VR.

“It’s a great way to validate selections you’re making round nitrogen in crop.

“We didn’t do it final 12 months; it was too moist to have a consequence.”

Protein guides enter

Broden Holland farms on sandy-loam nation in a household partnership that crops 3800ha and has 1200ha of lucerne clover in addition to operating 4500 merinos at Thuddungra on the south-west slopes.

Their rotation is a seven-year wheat-canola part, after which three years of pasture.

The Hollands don’t use DataFarming pictures, however are variable-rate appliers of nitrogen utilizing protein maps from the earlier 12 months’s wheat to dictate charges for fertiliser, which is broadcast after planting.

The technique is proving profitable in narrowing the unfold of wheat proteins from round 8.5-14.2pc within the 2016 harvest, to shut to inside 1pc in 2021, and common wheat yield can also be up from 4.5 tonnes per hectare in 2016 to 6t/ha in 2020 and 2021.

Utilizing information from protein maps, lime, gypsum, manure and urea are all unfold at variable charges.

“They’re the simple levers to tug.

“We’re specializing in getting all these even, after which getting our yield maps even.

“I’m saying: Let’s neglect about yield maps for the second and try to get our inputs even.”

“Low protein will get much more urea; excessive protein will get much less.”

The enterprise has prior to now blended roughly 1000 tonnes of wheat to keep away from reductions that will apply to their lowest-protein wheat.

“Now we haven’t blended; there’s simply no variation.”

Mr Holland stated deep N testing on 100ha carried out in March 2020 confirmed a confidence-building correlation between the earlier 12 months’s wheat protein and deep N ranges.

“In 2020, we unfold urea primarily based wholly and solely off protein.”

“Each time I haven’t unfold the map…I’ve kicked myself.”

An on-farm protein meter delivers grain outcomes earlier than every load leaves the farm.

“Each truckload we ship, we all know what it’s going to be.”

The Hollands provide wheat to the area’s flour mills, and stated the advantage of delivering hundreds inside a slim vary is primarily in elevated farm effectivity however not {dollars} per tonne.

Nonetheless, Mr Holland hopes that may change.

“There’s positively a dialogue available in displaying (mills) that we will ship them a single percentage- protein wheat…and get the consistency for them.”

Grain Central: Get our free information straight to your inbox – Click on right here