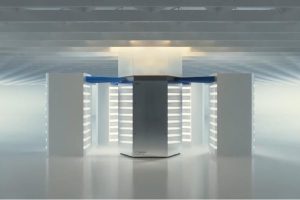

One of many key takeaways from the provision chain disaster we discover ourselves in is to extend visibility for all concerned. (Supply: ProLift Rigging)

On this version of Voices of the Business, Robert Moffit, Govt Vice President of BluePrint Provide Chain, explores the significance of transparency in provide chain administration.

Robert Moffit, Govt Vice President of BluePrint Provide Chain

Boots on the Floor Vantage Level

Over the past a number of years the information middle development market has been performing steadily and has began off very robust with a 29% improve from final yr’s first quarter, shared throughout a Dodge Information & Analytics mid-year development outlook. This robust begin may be attributed to the excessive demand for information as firms proceed the make money working from home pattern introduced on by the COVID lockdowns. Via our strategic partnership with ProLift Rigging, now we have continued to serve stakeholders with boots on the bottom help as they proceed to navigate this development demand with native warehousing, final mile hauling, and rigging help.

From our perspective and our companions boots on the bottom vantage level within the development course of, the synchronization of the manufacturing and supply of outsized and chubby essential merchandise to development websites has been a problem for the upstream Cloud Supplier. Effectively earlier than COVID restrictions and the current provide constraints, Cloud Suppliers skilled low visibility into dependable product prepared, ship, and supply dates on account of excessive competitors demand constraints.

Oftentimes, this leaves a number of layers of website contractors, reminiscent of ProLift Rigging, on standby and pushing development finish dates additional proper. An information middle market situations replace report by Turton Bond said that “delays are growing stress on schedules and driving development prices larger. Datacenter operators with a major concentrate on early procurement of key materials and tools (i.e. switchgear, UPS, chillers, mills, and so forth.) & constructing good relationships with distributors to ensure supply are discovering success in a tough market. Early procurements, off-site warehouse storage of key tools & locking in costs earlier than quarterly will increase is the present recipe for profitable procurement in a datacenter growth.”

Again in 2019 ProLift shared this identical sentiment in a DCF article, stating “your deliberate [data center construction] website is only a small piece to the booming information middle development market, and also you run a excessive danger of turning into misplaced within the demand […] if correct buffering isn’t allotted to your schedule.” That is extra related now than ever earlier than. The influence of COVID restrictions and world materials provide chain constraints have solely elevated these points, creating difficult dynamics for the Cloud Supplier to fulfill their essential development finish dates.

Creating this dynamic of essential product demand planning, proactive procurement, vendor relationship administration, logistics and transportation coordination, strategic warehouse areas, and website supply and set up requires excessive possession and visibility by all stakeholders concerned. Nonetheless, on the finish of the day or development venture, the Cloud Supplier is the one who takes the hit when excessive possession and visibility between stakeholders is lacking. With out transparency between all events, the information middle development course of is just not performing at max effectivity, resulting in website development delays, and missed alternatives for the Cloud Suppliers.

However who’s liable for advocating this transparency? We consider a robust development provide chain administration agency is the lacking piece to the transparency that’s desperately wanted.

Constructing Proprietor Enabled Provide Chains

From years’ price of conversations and experiences out there, it’s clear that many Cloud Suppliers are ready to grab market alternative they usually want a associate to assist fight the market constraints and speed up the scaling of an elite provide chain crew tailor-made to their measurement and operation. Cloud Suppliers want numerous ranges of help relying on their development plans and present operational constraints, reminiscent of instant procurement and logistics crew deployment and strategic sourcing of latest vendor companions to deploy bodily infrastructure sooner.

From our experiences partnering with Cloud Suppliers, essentially the most environment friendly and efficient solution to shortly deploy new information middle websites is to construct an unallocated stock of OFCI merchandise that may be predictably deployed to websites throughout the Cloud Supplier’s strategic geography. In easy phrases, decoupling the outsized and chubby essential cooling and energy merchandise from website degree development scope. To get there, legacy fashions of producing, procurement, transportation and development should be re-engineered in order that possession, incentives, metrics, and finally efficiency are aligned with the speedy innovation that impacts the Cloud Suppliers core markets.

What does this seem like? Listed below are a couple of methods Cloud Suppliers can rethink their provide chain and development course of to assist fight the present market constraints and finally construct sooner.

- Acquire Visibility and Commitments from Tier 2, 3+ Suppliers: Tier 1 Suppliers are being impacted by lack of uncooked materials, fabricated parts, sub-assemblies, and so forth. We consider there are strategic alternatives to determine strong relationships with Tier 2 and three suppliers to make sure Tier 1 OEMs and Integrators are positioned to fulfill their commitments. This might imply taking management of essential tier 1 inputs. Discovering a path to develop strategic sourcing providers to assist deal with this chance in each OFCI and CFCI procured merchandise is essential, whether or not that’s self-developed or a strategic associate positioned to help this effort.

- VMI and Security Inventory/Buffered Stock of OFCI Tools: Dynamic demand to assemble and ship further 40+ MW capability inside the “want by” constraints requires OFCI delays to be eradicated. With demand fashions that inform VMI and owned Stock ranges, homeowners want an answer to handle order execution and manufacturing, receipt and administration of that stock (chain of custody, high quality, guarantee, dealing with). Moreover, strategically positioned warehouse services are instrumental to the versatile deployment of apparatus. Not solely within the markets presently being focused, however the capacity to develop these capabilities shortly.

- Shift Transportation Scope Duty from Suppliers and Producers to a Single Accountable Social gathering: Producers do not need a strategic concentrate on transportation. Their focus is on growing manufacturing functionality and capability. Even when a producer is expert in procuring and coordinating transportation, Cloud Suppliers will expertise fragmented transportation coordination as a result of every of the assorted suppliers are liable for the transportation of their product. It is a main explanation for the shortage of visibility to the whole provide chain inevitably resulting in delays and inefficiencies.

- Shift Final Mile Supply and Website Rigging from Suppliers and Website Subcontractors to a Single Accountable Specialty Contractor: The final mile supply and website rigging is already being carried out and executed at each venture website, however with little management or visibility to the Cloud Supplier. These rigging prices are already being incurred on the venture degree upstream to the Cloud Suppliers. By shifting the accountability to a single supplier, these prices will probably be shifted out of the Integrator, Basic Contractor, M&E Subcontractor, and native Crane and Rigging Subcontractor scopes. This transfer has the chance to avoid wasting a minimum of 20% or extra on mark-up prices alone and permit for an owner-enabled provide chain. The important thing right here is for the positioning to be utterly prepared for the Cloud Supplier’s merchandise previous to specialty contractors’ deployment to the sphere, eliminating standby time and rework. The right mannequin is the “shell forward” mannequin the place all civil, underground, foundations, and constructing shells are full previous to the proprietor’s merchandise being set, permitting for faster set up, sooner hookup, and decrease general heavy rigging prices.

Robert Moffit is the Govt Vice President of BluePrint Provide Chain. BluePrint Provide Chain accelerates the leaders of the commercial future, by strengthening, scaling, and constructing a resilient development provide chain. Contact them to be taught extra about their processes that give clear visibility into the whole provide chain, finally creating an ‘Proprietor Enabled Provide Chain’.