The silicon-based pc chips that energy our fashionable gadgets require huge quantities of power to function. Regardless of ever-improving computing effectivity, info know-how is projected to devour round 25% of all major power produced by 2030. Researchers within the microelectronics and supplies sciences communities are searching for methods to sustainably handle the worldwide want for computing energy.

Scientists flip century-old materials into a skinny movie for next-gen reminiscence and logic gadgets

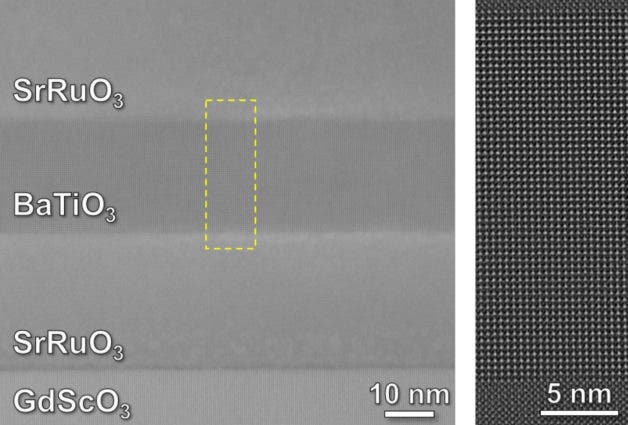

Electron microscope pictures present the exact atom-by-atom construction of a barium titanate (BaTiO3) skinny movie sandwiched between layers of strontium ruthenate (SrRuO3) steel to make a tiny capacitor. (Credit score: Lane Martin/Berkeley Lab)

The holy grail for decreasing this digital demand is to develop microelectronics that function at a lot decrease voltages, which might require much less power and is a major objective of efforts to maneuver past right this moment’s state-of-the-art CMOS (complementary metal-oxide semiconductor) gadgets.

Non-silicon supplies with attractive properties for reminiscence and logic gadgets exist; however their frequent bulk type nonetheless requires giant voltages to control, making them incompatible with fashionable electronics. Designing thin-film options that not solely carry out effectively at low working voltages however will also be packed into microelectronic gadgets stays a problem.

Now, a workforce of researchers at Lawrence Berkeley Nationwide Laboratory (Berkeley Lab) and UC Berkeley have recognized one energy-efficient route — by synthesizing a thin-layer model of a widely known materials whose properties are precisely what’s wanted for next-generation gadgets.

First found greater than 80 years in the past, barium titanate (BaTiO3) discovered use in varied capacitors for digital circuits, ultrasonic turbines, transducers, and even sonar.

Crystals of the fabric reply rapidly to a small electrical discipline, flip-flopping the orientation of the charged atoms that make up the fabric in a reversible however everlasting method even when the utilized discipline is eliminated. This supplies a strategy to change between the proverbial “0” and “1” states in logic and reminiscence storage gadgets — however nonetheless requires voltages bigger than 1,000 millivolts (mV) for doing so.

In search of to harness these properties to be used in microchips, the Berkeley Lab-led workforce developed a pathway for creating movies of BaTiO3 simply 25 nanometers skinny — lower than a thousandth of a human hair’s width — whose orientation of charged atoms, or polarization, switches as rapidly and effectively as within the bulk model.

“We’ve recognized about BaTiO3 for the higher a part of a century and we’ve recognized tips on how to make skinny movies of this materials for over 40 years. However till now, no person may make a movie that would get near the construction or efficiency that might be achieved in bulk,” stated Lane Martin, a college scientist within the Supplies Sciences Division (MSD) at Berkeley Lab and professor of supplies science and engineering at UC Berkeley who led the work.

Traditionally, synthesis makes an attempt have resulted in movies that include larger concentrations of “defects” — factors the place the construction differs from an idealized model of the fabric — as in comparison with bulk variations. Such a excessive focus of defects negatively impacts the efficiency of skinny movies. Martin and colleagues developed an strategy to rising the movies that limits these defects. The findings have been revealed within the journal Nature Supplies.

To grasp what it takes to supply the most effective, low-defect BaTiO3 skinny movies, the researchers turned to a course of referred to as pulsed-laser deposition. Firing a robust beam of an ultraviolet laser gentle onto a ceramic goal of BaTiO3 causes the fabric to rework right into a plasma, which then transmits atoms from the goal onto a floor to develop the movie. “It’s a flexible device the place we are able to tweak a whole lot of knobs within the movie’s development and see that are most vital for controlling the properties,” stated Martin.

Martin and his colleagues confirmed that their technique may obtain exact management over the deposited movie’s construction, chemistry, thickness, and interfaces with steel electrodes. By chopping every deposited pattern in half and its construction atom by atom utilizing instruments on the Nationwide Heart for Electron Microscopy at Berkeley Lab’s Molecular Foundry, the researchers revealed a model that exactly mimicked an especially skinny slice of the majority.

“It’s enjoyable to assume that we are able to take these basic supplies that we thought we knew every part about, and flip them on their head with new approaches to creating and characterizing them,” stated Martin.

Lastly, by putting a movie of BaTiO3 in between two steel layers, Martin and his workforce created tiny capacitors — the digital parts that quickly retailer and launch power in a circuit. Making use of voltages of 100 mV or much less and measuring the present that emerges confirmed that the movie’s polarization switched inside two billionths of a second and will doubtlessly be sooner — aggressive with what it takes for right this moment’s computer systems to entry reminiscence or carry out calculations.

The work follows the larger objective of making supplies with small switching voltages, and inspecting how interfaces with the steel parts mandatory for gadgets influence such supplies. “This can be a good early victory in our pursuit of low-power electronics that transcend what is feasible with silicon-based electronics right this moment,” stated Martin.

“Not like our new gadgets, the capacitors utilized in chips right this moment don’t maintain their information except you retain making use of a voltage,” stated Martin. And present applied sciences usually work at 500 to 600 mV, whereas a skinny movie model may work at 50 to 100 mV or much less. Collectively, these measurements exhibit a profitable optimization of voltage and polarization robustness — which are typically a trade-off, particularly in skinny supplies.

Subsequent, the workforce plans to shrink the fabric down even thinner to make it appropriate with actual gadgets in computer systems and research the way it behaves at these tiny dimensions. On the similar time, they may work with collaborators at corporations comparable to Intel Corp. to check the feasibility in first-generation digital gadgets. “In case you may make every logic operation in a pc one million occasions extra environment friendly, assume how a lot power you save. That’s why we’re doing this,” stated Martin.

This analysis was supported by the U.S. Division of Power (DOE) Workplace of Science. The Molecular Foundry is a DOE Workplace of Science person facility at Berkeley Lab.

Berkeley Lab’s “Past Moore’s Legislation” initiative goals to establish pathways to ultralow energy logic in reminiscence components. “We have to get to low-voltage operation, since that’s what scales the power,” stated co-author Ramamoorthy Ramesh, a senior college scientist at Berkeley Lab and professor of physics and supplies science and engineering at UC Berkeley. “This work demonstrated, for the primary time, the switching discipline of the mannequin materials, BaTiO3 with voltages decrease than 100 mV, on a related platform.”

Article courtesy of Lawrence Berkeley Nationwide Laboratory (Berkeley Lab).

Associated: World Provide Shortages: No Time, No Chips — No Downside For NREL

Featured picture: A macro of a silicon wafer, by Laura Ockel on Unsplash

Try our model new E-Bike Information. In case you’re interested by electrical bikes, that is the most effective place to start out your e-mobility journey!

Admire CleanTechnica’s originality and cleantech information protection? Take into account turning into a CleanTechnica Member, Supporter, Technician, or Ambassador — or a patron on Patreon.