Collapsing bridges, crumbling aqueducts, and corroding highways: Infrastructure is massive (and more and more pressing) information within the U.S. A brand new class of robots and inspection drones from quite a lot of distributors are starting to scale constructions and carry out acrobatic flybys to discern the true state of affairs.

With federal {dollars} for infrastructure growing, the know-how might have extra public sector functions. However how massive a distinction can robots make? Is it too little too late for long-overlooked infrastructure issues? And is the regulation of autonomous methods preserving tempo with the know-how?

To reply these questions and extra, I related with Jake Loosararian, CEO and co-founder of Gecko Robotics, which leverages robotics as a service to carry out industrial inspections in essential industries resembling energy, oil and gasoline, and protection. Gecko’s wall-crawling robots scale alongside industrial belongings inspecting for injury whereas accumulating 1000x extra information factors than conventional inspection strategies at 10x the velocity. They’re furnished with cameras and sensors to detect corrosion, pitting, cracking, blistering, or laminations, they usually embody a powerful intersection of applied sciences, together with robotics, AI, and machine imaginative and prescient.

GN: Let’s begin with the headline: What’s at stake if we do not get infrastructure proper?

Jake Loosararian: Briefly, our way of life. Broken infrastructure can imply elevated energy outages, costlier utilities and transportation, shortages of important items, and manufacturing and provide chain disruptions affecting many different elements of the financial system. There’s additionally the chance of catastrophic disasters affecting workplaces and communities alike. Longer-term, it is also essential to acknowledge that we’re nonetheless extremely depending on conventional power sources, and if we will not meet present wants at a value that societies can bear, it’ll dramatically set again our capability to transition to cleaner types of power. And this can solely get harder within the face of inflation, geopolitical unrest, and world financial uncertainty.

GN: Okay, so fairly essential stuff then. Let’s discuss options. Why are robots changing into a essential device for infrastructure inspection?

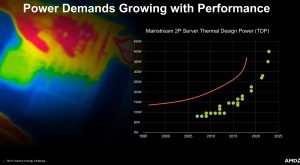

Jake Loosararian: Globally, nationally, and regionally, we’re going through a looming power disaster, and whereas there may be numerous concentrate on fuels and different inputs, it is also an infrastructure disaster. Within the close to time period, we have to maximize each the manufacturing capability and helpful lifetime of the belongings we’ve got, that are being strained as by no means earlier than by age, in addition to excessive climate and surges in demand. And whereas power is essentially the most noticeable instance, the identical is true of the infrastructure underpinning many different elements of every day life, together with transportation, water, chemical compounds, paper and pulp merchandise, and so forth. Maximizing the capability and well being of those belongings requires floor fact within the type of correct, wealthy, and consultant information and robots can seize 1,000x as a lot information as conventional strategies, 5-10x sooner, with ~75% fewer personnel. Along with the proper software program, robotic information seize and processing can drive the analyses wanted to carry out repairs, replacements, preventative upkeep, and operational changes, in addition to guiding funding in new infrastructure the place applicable.

Security can also be a significant profit: robots can function in locations people both cannot or should not and might cut back and even get rid of the necessity for inspectors to work excessive off the bottom, close to sizzling surfaces (as much as 240F) or in confined areas with potential publicity to hazardous chemical compounds. On the similar time, robots can really make human inspectors extra priceless by informing their work with higher, richer, and greater information and permitting them to concentrate on their distinctive worth add.

Robotic inspections are a significant safeguard towards environmental injury, whether or not within the type of a catastrophic accident or on a regular basis leaks and contamination.

GN: Sounds alluring. So how do your robots work, and what types of use circumstances are we speaking about?

Jake Loosararian: Our robots are outfitted with ultrasonic transducers, localization sensors, lasers, and HD cameras. They climb vertically and horizontally, adhering to surfaces magnetically, to examine tanks, boilers, pipes, stress vessels, digesters, hydropower tools, dams, ships, and different belongings for adjustments in thickness, cracks, corrosion, blistering, and different types of degradation. Our robots are remote-controlled and use a number of sorts of ultrasonic non-destructive testing methods, together with Speedy Ultrasonic Gridding, Speedy Automated Ultrasonic Testing, Phased Array Ultrasonic Testing, and our newest improvement, Trilateral Phased Array. Our robots purchase information at a beforehand unknown scale and constancy, and our information methods and software program enable human consultants to show that info into very important operational and strategic selections. When it comes to use circumstances, Gecko is at present targeted on essential industries, together with energy, oil and gasoline, chemical compounds, pulp and paper, heavy manufacturing, water storage, transportation, and protection.

GN: We have heard loads about inspection drones just lately as effectively. Would you think about {that a} aggressive know-how, and if that’s the case, what benefits do wall-crawling robots have over drones?

Jake Loosararian: It is not an apples-to-apples competitors as a result of they’re good at various things and are typically used accordingly. For our use circumstances, wall-crawling robots have a number of distinct benefits over drones. Robots have way more highly effective ultrasonic testing (UT) information acquisition capabilities than drones, making them higher suited to gather information at a scale wanted to reliably inform refined fashions, whereas drones are typically used for visible representations. Robots can have over 100 transducers on them, making them excellent for capturing metallurgical information round thickness, corrosion and cracking. Robots additionally accumulate huge quantities of floor fact information. Drones are greatest at picture seize, which is beneficial however would not let you know what is going on on on the planet of the unseen. Robots and drones are two completely different instruments at two completely different ranges of complexity – suppose welding torch vs. screwdriver. (For a more in-depth look, see Gecko’s December 2021 weblog put up evaluating crawlers and drones).

GN: One of many cool issues for me is that this know-how is not hypothetical; it is really getting used. Any buyer success tales you may share?

Jake Loosararian: We have been capable of revolutionize Shell’s inspections, beginning with an inspection of the tank roof of its Convent Refinery. Throughout that inspection, the robotic was capable of accumulate 1,000 instances the variety of measurements as a human inspector would in a tenth of the time.

In our work with Siemens Vitality, Gecko’s robots allow inspections to be carried out 5 to 10 instances sooner with 99.6% extra protection than guide inspections. We additionally eradicated the necessity for scaffolding and confined area entry. We work with BP as effectively, beginning with an inspection at BP’s Blackhawk central gas-treating heart in late 2020. That first inspection took 4 days, as in comparison with the earlier inspection time of 4 weeks, collected 7.3 million measurements, and price 75% lower than earlier vessel inspections.

In Oklahoma, we did an inspection of the above-ground storage tank of a 60,000 bpd refinery. They switched to our providers not solely as a result of we might present orders of magnitude extra information than a human inspector however due to the pointless threat having an inspector on the tank roof posed. Folks strolling round on the tank roof couldn’t solely injury the tank, however they may additionally simply and severely damage themselves accidentally. We have additionally had intensive success inspecting energy plant boilers, extending upkeep home windows and, in some circumstances stopping pricey pressured outages.

At certainly one of SE Asia’s largest biomass crops, a Gecko inspection group of 4 personnel was capable of accumulate 500x extra information than the earlier inspection group of 20 and make preventative upkeep suggestions that decreased the frequency of deliberate outages equating to tens of tens of millions of {dollars} in potential financial savings.